SMMS Non-Woven Manufacturers

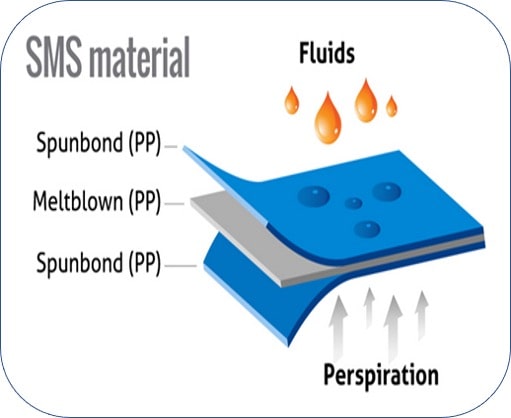

SMMS (SPUNBOND + MELTBLOWN +MELTBLOWN+ SPUNBOND) consists of continuous 100% polypropylene (PP) threads arranged at random and thermally welded by a calendering process, or Spunlaid thermo bonded method, plus a melt-blown layer and then another of spun-bonded polypropylene.

Advantage This is a high coverage Non-woven fabric. It is low weight, high longitudinal and transversal strength and soft feel make it suitable for use in the medical and hygiene industry. It can be given special treatments to give it certain properties (hydrophilic, anti-bacterial, oil-repellent, alcohol-repellent and blood-repellent).

Performance Non toxic and tasteless, high isolation bacteria. Through special processing equipment, to achieve anti-static, anti-alcohol, anti-blood plasma, water repellent and water production and other properties.

Product Specifications

| S.No | Specification | Range |

|---|---|---|

| 1 | GSM | 8 To 80 GSM |

| 2 | Width | 50mm To 1600mm |

| 3 | Grade | Export/Domestic |

| 4 | Colour | Customised |

| 5 | MOQ | 1 Ton |

| 6 | Transport Package | Packed by PE film |

| 7 | Origin | India |